Non-Fried Instant Noodle Making Machine

Keywords:

non-fried instant noodle making machine

- Description

-

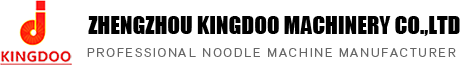

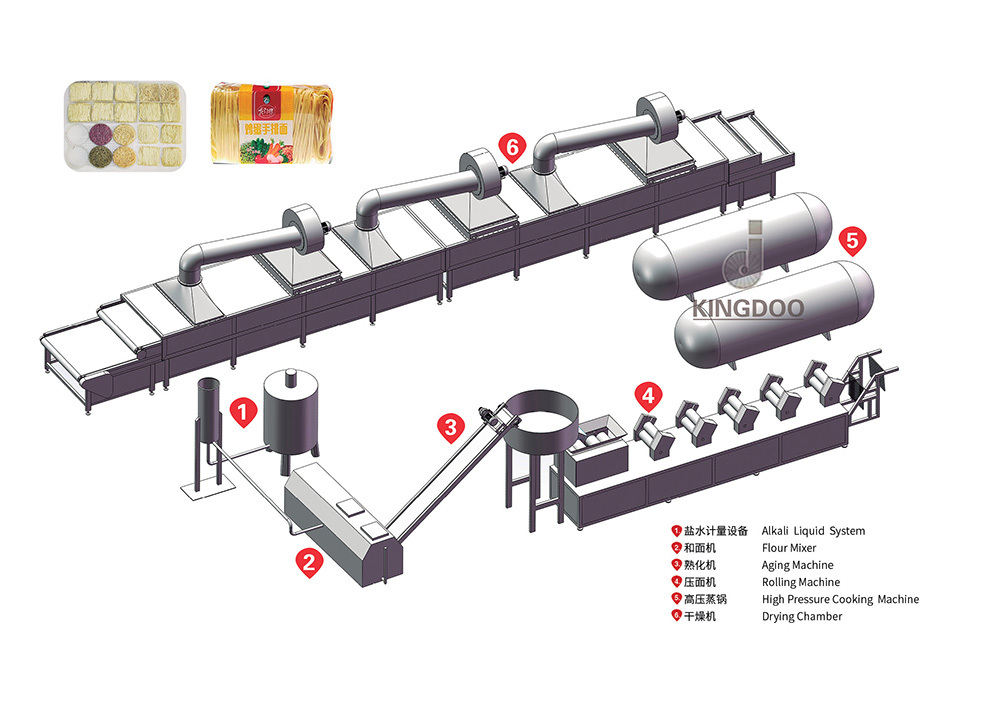

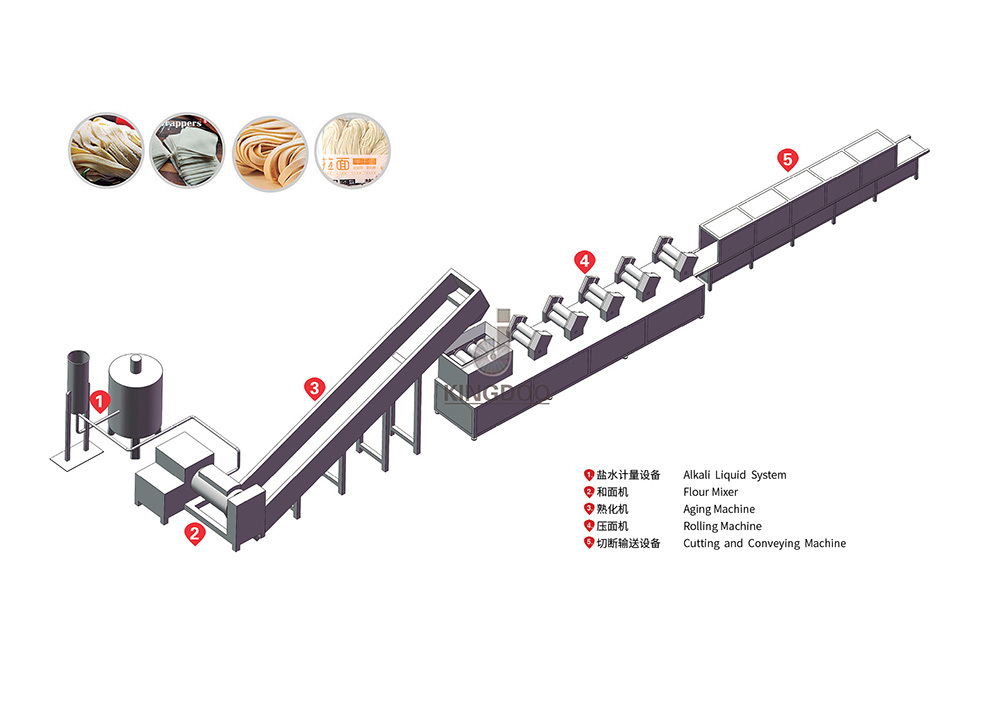

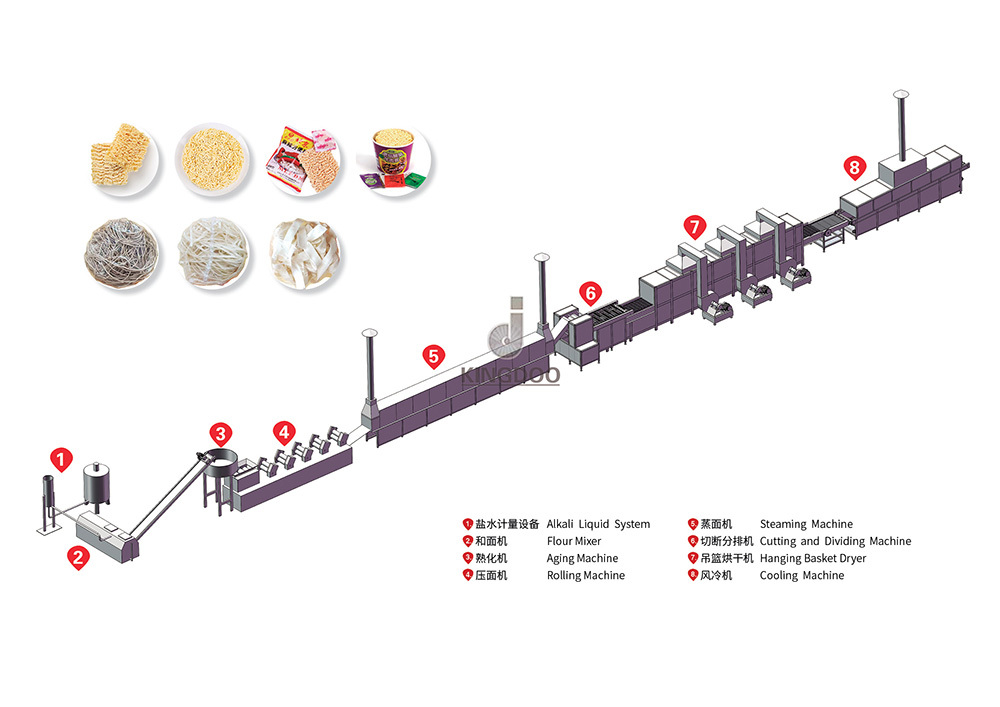

Non-fried instant noodles production line includes salt water mixing and measuring, flour mixing,dough aging, dough pressing, steaming, cutting and dividing, drying, air cooling, packaging. The entire line adopts steam heating method and it can produce square dried noodles or circular dried noodles, with a production capacity 20000 to 300000 pieces in 8 hours.

ADVANTAGE

1.Healthier Option:

●Oil content is relatively low, so it is close to raw flour and has a light taste.

●Not going through the frying process and it is more beneficial for health. Noodles have the characteristic of being fine and dense.

2.Extended Shelf Life:

●Non-fried instant noodles have a lower moisture content, Thereby delaying the speed of noodle spoilage.

●The extended shelf life can be advantageous for both manufacturers and retailers in terms of storage and distribution.

3.Low production cost

●Making fried instant noodles requires a large amount of palm oil. But non-fried instant noodles no need palm oil, saving production costs.

●Of course, we will never meet oil spoilage problem.Wheat flour is the most needed raw material.

Product parameters

Model

power

Steam consumption

Dimension(m)

(multi- layer steamer)Worker

30,000pieces/8h

50kw

1000-1200KG/H

50*5*4

4

60,000pieces/8h

65kw

1500-1700KG/H

55*5*4

4

80,000pieces/8h

80kw

2000-2200KG/H

65*6*4

5

120,000pieces/8h

95kw

2400-2600KG/H

75*6*4

5

160,000pieces/8h

115kw

2800-3000KG/H

85*7*4.5

5

200,000pieces/8h

130kw

3200-3400KG/H

95*8*4.5

6

250,000pieces/8h

140kw

3600-3800KG/H

105*8*4.5

6

300,000pieces/8h

155kw

3800-4000KG/H

120*10*4.5

6

PRODUCT DETAILS

Alkali water mixing and measuring system

Flour mixer

Dough aging machine

Rolling machine

Steaming machine

Cutting and dividing machine

Hanging basket dryer

Cooling machine

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!