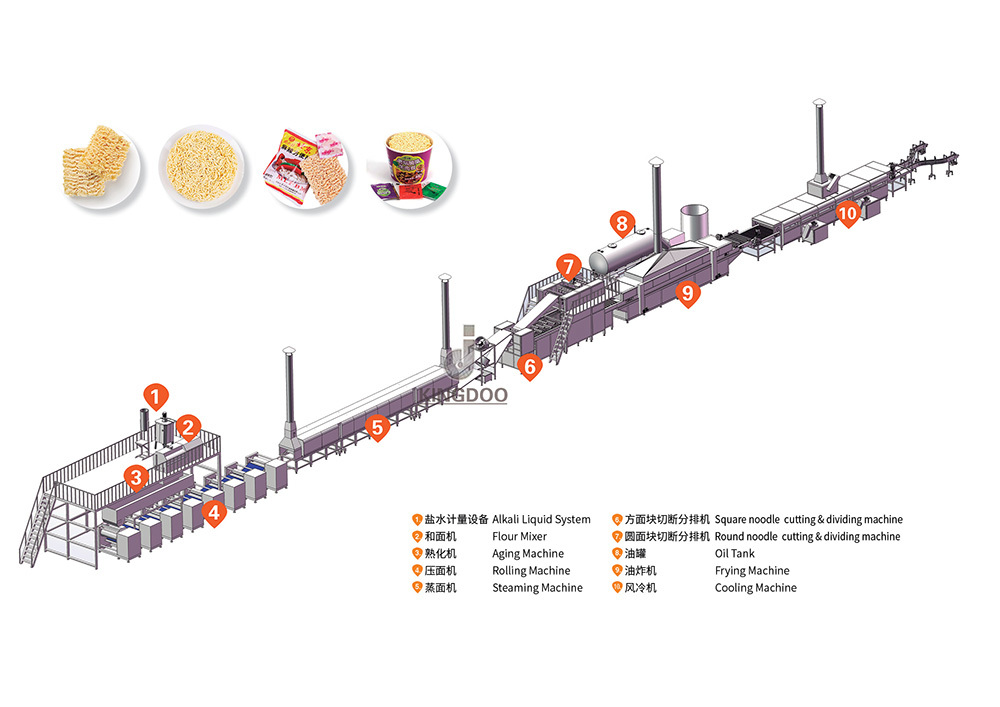

Fried Instant Noodle Making Machine

Keywords:

fried instant noodle making machine

- Description

-

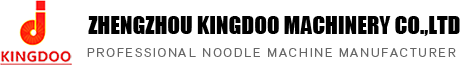

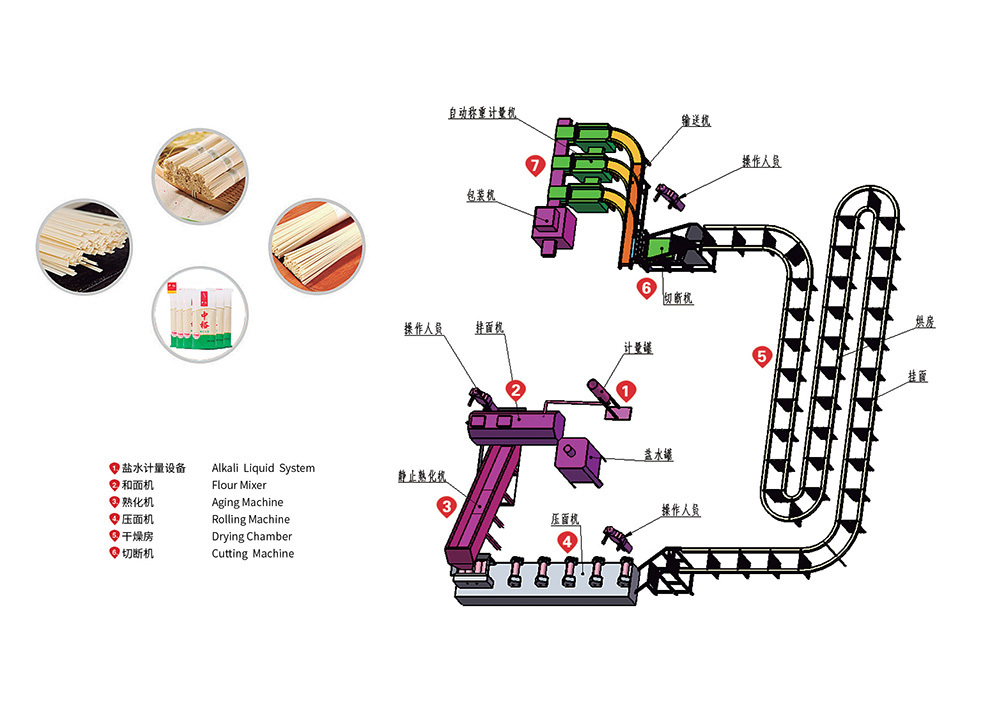

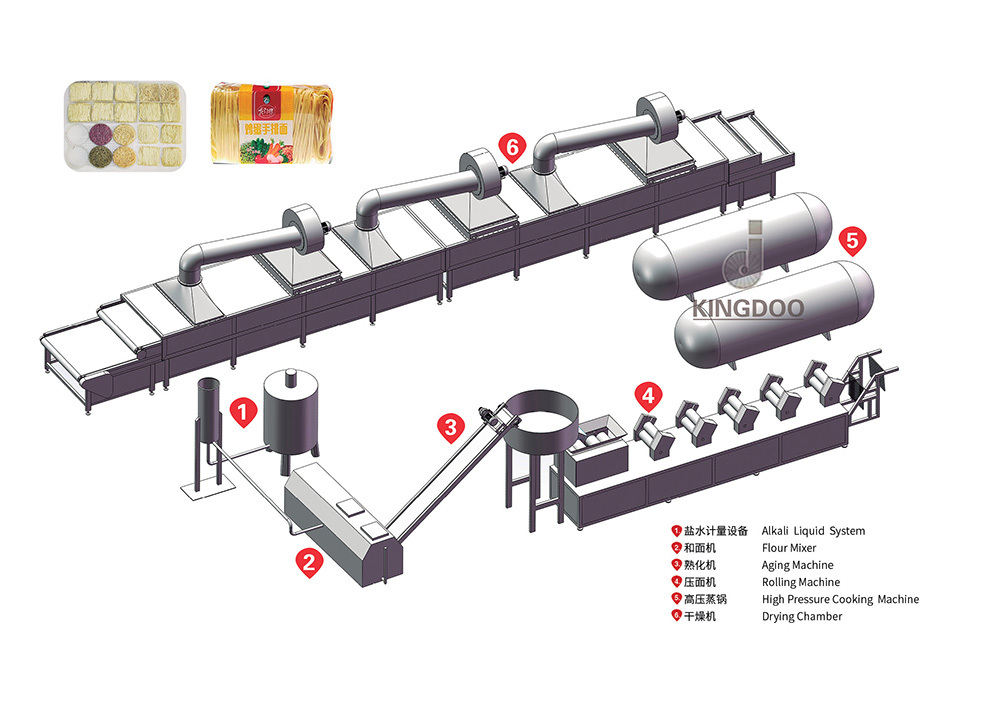

Our factory has over 20 years experience for manufacturing fried instant noodle making machine. The fried instant noodle production line from A to Z include salt water mixer ,flour mixer ,aging machine,rolling machine,steamer ,cutting and dividing machine,fryer ,cooling machine, packing machine, steam boiler .

ADVANTAGE

1.High automation ,PLC controlled

●Main process of the equipment using frequency control, photoelectric tracking, PLC program control, to achieve a full range of synchronous coordination control.

●Noodle cutting speed is adjustable without stopping machine, oil temperature is controlled automatically .

2.High efficiency ,saving man power

●Noodle cut,fold and drop into fryer boxes automatically.

●Usually need 4 worker to operate this noodle line without packing staffs.

3.Easy operation, repair and maintenance

●Fried instant noodle making machine process is already very mature and has a long history. In addition, continuous improvement and optimization have made instant noodle production line design very reasonable.

●Our touch screen match WIFI and remote operation function.Our engineer can solve problem even in different countries.

4.Noodle production precision

●The noodle shape which produced by machine is regular, and weight is controlled within plus or minus three grams.

●Noodle producing process controlled from water feeding ,flour adding ,dough pressing,steaming ,cutting and dividing,frying,cooling. These steps are all very accurate.

Product parameters

Model

power

Steam consumption

Dimension(m)

(multi- layer steamer)Worker

30,000pieces/8h

42kw

800-1000KG/H

40*5*4

4

60,000pieces/8h

56kw

1200-1400KG/H

45*5*4

4

80,000pieces/8h

68kw

1600-1800KG/H

55*6*4

5

120,000pieces/8h

83kw

2000-2200KG/H

65*6*4

5

160,000pieces/8h

106kw

2400-2600KG/H

75*7*4.5

5

200,000pieces/8h

114kw

2800-3000KG/H

80*8*4.5

6

250,000pieces/8h

125kw

3200-3400KG/H

90*8*4.5

6

300,000pieces/8h

140kw

3600-3800KG/H

90*10*4.5

6

Product details

Alkali water mixing and measuring system

Flour mixer

Dough aging machine

Rolling machine

Steaming machine

Cutting and dividing machine

Frying machine

Cooling machine

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!