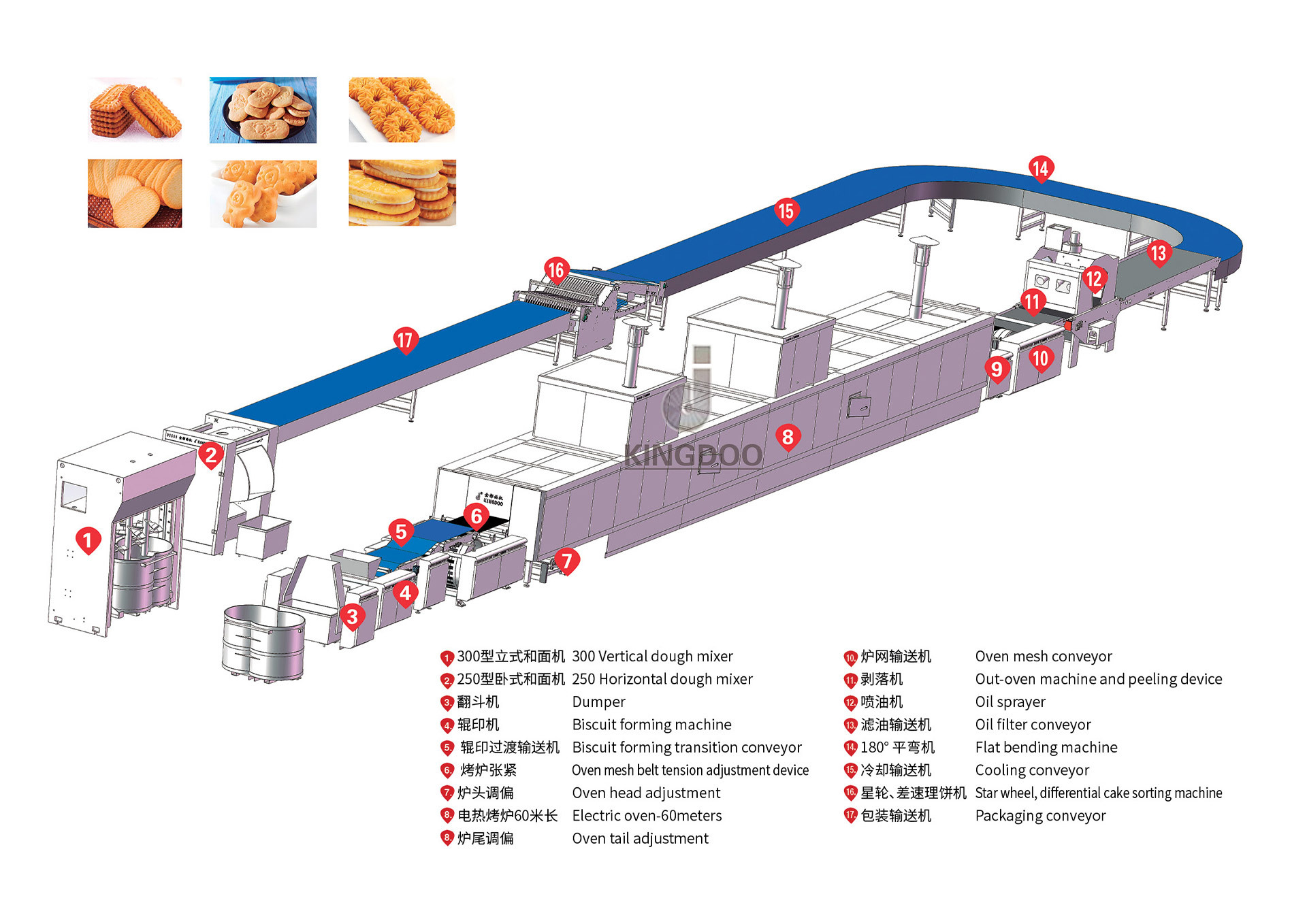

Biscuit Production Line

Keywords:

biscuit production line

cookie production line

- Description

-

Our company produces different types of biscuit production lines, and can produce multiple categories of biscuit products according to different processes: Crisp biscuits, such as: Oreo biscuits, black biscuits, boat biscuits, monkey mushroom biscuits, caramel biscuits, etc.; Tough biscuits, such as: high calcium biscuits, coconut biscuits, multi-grain biscuits, etc.; Our company's production line is controlled by an advanced PLC system. Different models of production lines can meet different production capacity requirements, and the output can be selected from 1500kg to 17000kg/8 hours.

Crispy biscuit production line process flow:

Dough mixing - roller forming - tunnel oven baking - oil spraying - cooling - finishing - packaging

Tough biscuits production line process flow:

Dough mixing - laminating - pressing - roller forming - tunnel oven baking - oil spraying - cooling - finishing - packaging

Model

Capacity(kg/h)

Electric furnace tunnel power(kw/h)

Natural gas tunnel furnace power

(kw/h)

Gas consumption of natural gas tunnel furnace (m³/h)

Dimension(m)(L*W*H)

Worker

Crisp biscuit production line

400

200-350

300

34

13-20

95*4*3.5

4-5

600

450-600

650

98

23-35

100*5*3.5

800

700-900

1150

175

35-50

120*5*3.5

1000

1100-1400

1450

190

45-60

120*6*3.5

1200

1500-1700

1800

210

55-75

120*6*3.5

Tough biscuit production line

400

200-350

300

34

15-23

115*4*3.5

4-5

600

450-600

650

98

35-50

120*5*3.5

800

700-900

1150

175

45-55

140*5*3.5

1000

1100-1400

1450

190

50-70

140*6*3.5

1200

1500-1700

1800

210

60-80

140*6*3.5

Horizontal Mixer

Biscuit forming machine

Hot-air circulation electric baking oven (Including PLC control system)

Oven driven (including Correction system)

Out-oven machine and peeling device

Oil sprayer

Stacker(star wheel & discrepancy speed)

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!