Dough Leaf Production Line

Keywords:

Dough leaf production line

- Description

-

Product parameters

Model

Capacity

Power(kw)

Area(L*W*H)

Steam consumption

Worker

330

200kg/h

25

25x10x3

1000kg/h

4

350

300kg/h

40

35x10x3

1200kg/h

4

450

400kg/h

50

40x10x3

1400kg/h

4

550

500kg/h

60

45x10x3

1600kg/h

5

650

600kg/h

70

50x10x3

1800kg/h

5

800

700kg/h

80

55x10x3

2000kg/h

5

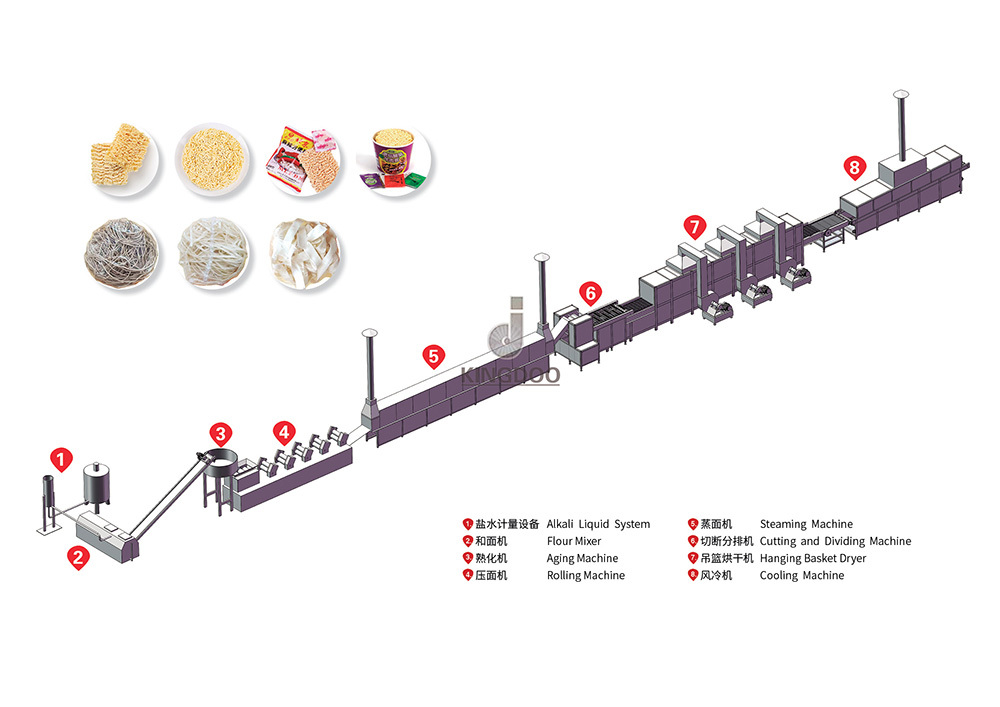

Now there are two types dough leaf production lines. One is raw dough leaf,the other is steam ripe dough leaf.

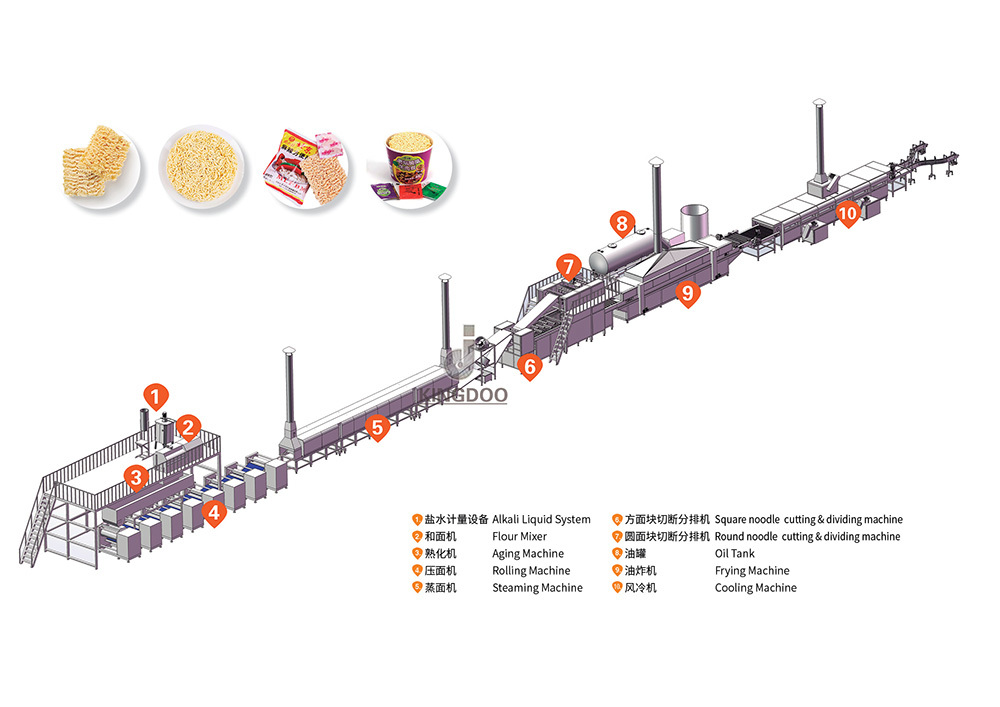

1. Raw dough leaf production line

The dough leaf production line includes salt water mixing tank, salt water metering tank,flour mixing machine, curing machine, noodle pressing machine , conveyor, mesh belt dryer, finished product conveyor. We can change noodle slitter to produce different dough leaf shape .usually it’s square, rhombus, etc. The dough leaf is usually lighter and thinner, so the output is not as high as fresh noodle when use same model.

There are two forms dough leaf dryer, one is teflon mesh belt and the other is stainless steel mesh belt. It is recommended to use stainless steel mesh belt for large production, and the drying time is about 40 minutes. Our company can design dryers with different levels according to the customer's workshop, usually is 3, 5, 7 layers etc. The heating and drying methods by dryer is steam type. The produced dough leaves should not be too crispy or too wet, otherwise it is not easy to store. Our company has much experience in this area and can ensure the dough leaf quality .

The output ranges from 200 kilograms to 1000 kilograms per hour.

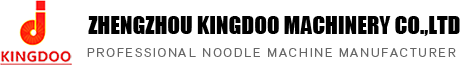

2. Steam ripe dough leaf production line

This line need use steaming machine , and process is little different with raw dough leaf production. Final dough leaf shape is waving and square.

It’s belong fast food, usually packed into a bowl or cup. People just put hot water into bowl and wait for 5 minutes ,then can eat directly with sauce.

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!