Dried stick noodle making machine

Keywords:

Dried stick noodle making machine

- Description

-

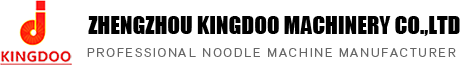

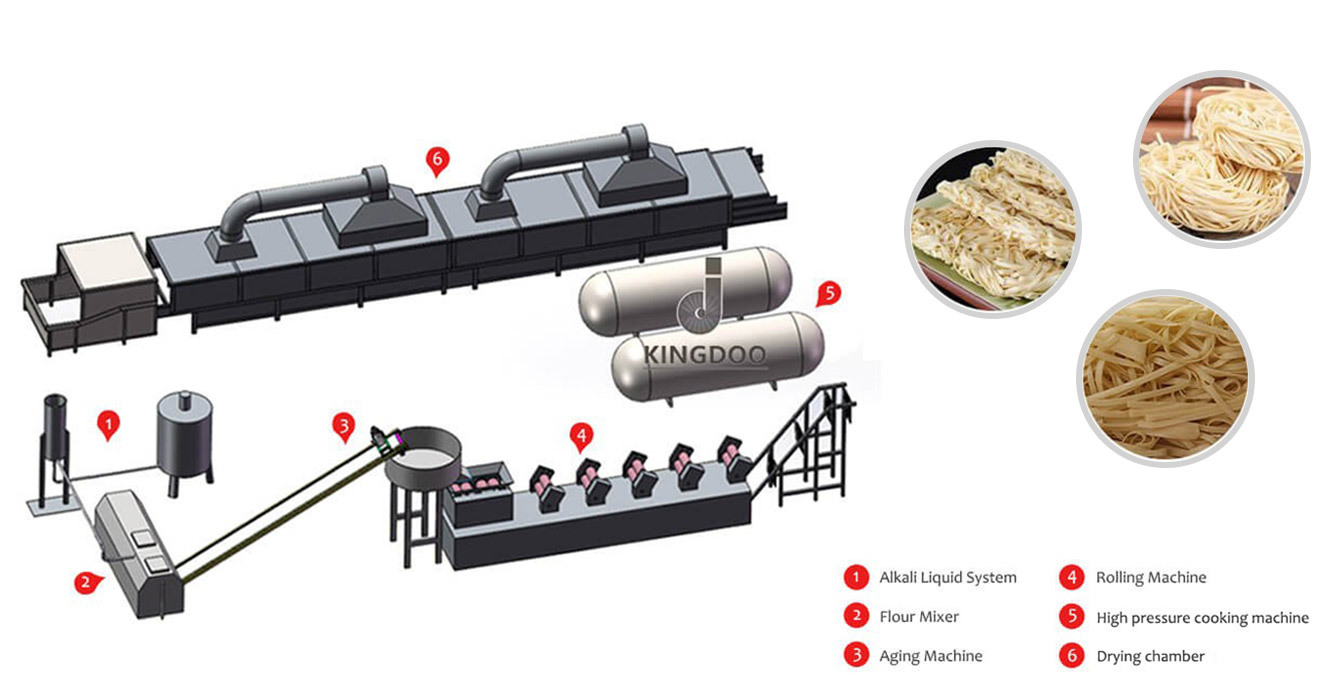

The automated continuous dried stick noodle making machine include alkali water mixer, measuring water supply, flour mixing,aging, compound rolling machine, continuous rolling machine, slitting, shelf transportation, cutting the bottom of noodle neatly, drying and putting- down, cutting and packing.

Dried stick noodle making machine usually cut into 12cm to 30 cm . Drying time is about 4 hours .Material is wheat flour . But we can add little vegetable powder or sauce, egg powder to make change into other color . There are two types drying way, one is several lines go ahead straightly together . The other type is only one line go ahead circularly.

The capacity is from 300kg per hour to 2000kg per hour.Roller width is 300 to 1000 mm. The size can customized by customer.

Product parameters

Model

Capacity(kg/8h)

Area(L*W*H)

Power(kw)

Worker

330

2500

30x6x3.5

30

4

350

4000

40x7.2x3.5

38

4

450

5000

45x9.6x3.5

45

4

550

6000

50x10.3x3.5

59

4

650

8000

55x10.3x3.5

75

4

765

10000

60x15x3.5

85

5

800

12000

60x15x3.5

95

5

1000

16000

65x18x3.5

110

6

PRODUCT DETAILS

Alkali water mixing and measuring system

Flour mixer

Dough aging machine

Rolling machine

Drying room equipment

Dried stick noodle cutting machine

Stick noodle packing machine

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!