Boiled and steam noodle making machine

Keywords:

Boiled and steam noodle making machine

- Description

-

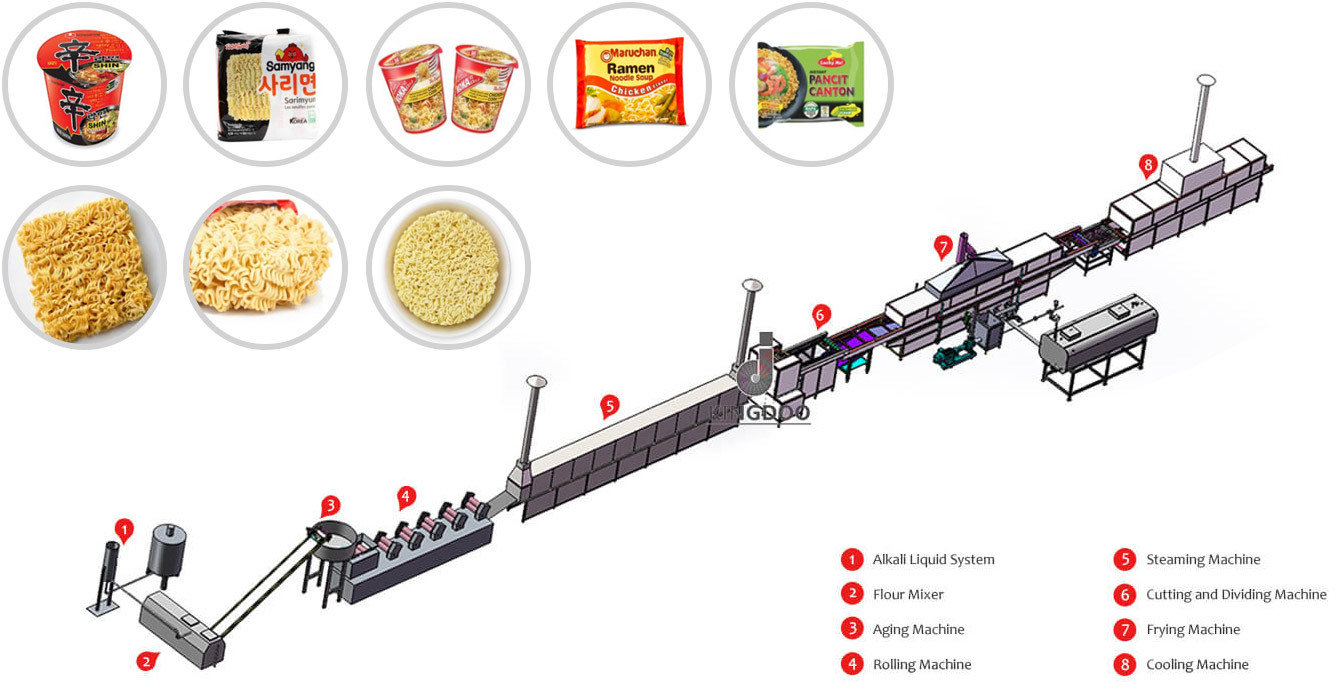

Boiling noodle production line

Sometimes boiling noodle also called fresh noodle , boiling noodle making machine process:Alkali water mixer --- flour mixing ----- aging ----- pressing roll machine ---- boiling machine ---- cooling machine ---- cutting ----- packing

Making boiling noodle need add some soda.

We have made boiling noodle making machine over 10 years. And we can make it from small to big capacity.

Steam noodle production line

Steam noodle making machine process: alkali water mixing ---- flour mixing ----- aging ----- dough pressing ----- cutting into strip ---- steaming ----- cooling ------ cutting.

There are two kind of steamer.One is single layer continuous steamer.The other kind is three layer continuous steamer.Single layer steamer is longer than three layer steamer.Customer can choose accord the workshop size.

Boiling noodle production line and Steam noodle production line difference

In a boiling noodle production line, the noodles are immersed in boiling water for a specific duration.

Boiling helps cook the noodles quickly, resulting in a soft and tender texture.

After boiling, the noodles undergo a blanching or rinsing step to remove surface starch and cool them down.

Blanching also helps to set the color of the noodles and prevent overcooking.

Boiling tends to produce noodles with a softer and more elastic texture.

Boiled noodles are often used in various dishes such as soups, stir-fries, and noodle bowls.

In a steam noodle production line, the noodles are exposed to steam for cooking.

Steaming is a gentler cooking method compared to boiling, and it results in a firmer texture.

Steaming Equipment:

The production line for steam noodles includes specialized equipment for steaming, such as steam chambers or steaming machine.

Steam-cooked noodles tend to have a firmer and chewier texture.

These noodles are often used in dishes where a more substantial and toothsome texture is desired.

Product parameters

Model

Capacity

Power(kw)

Area(L*W*H)

Steam consumption

Worker

330

400kg/h

30

40x10x3

1000kg/h

4

350

600kg/h

45

50x15x3

1500kg/h

4

450

800kg/h

60

60x15x3

2000kg/h

4

550

1000kg/h

70

70x20x3

2300kg/h

5

650

1200kg/h

80

75x20x3

2500kg/h

5

800

1500kg/h

90

80x20x3

3000kg/h

5

PRODUCT DETAILS

Alkali water mixing and measuring system

Flour mixer

Dough aging machine

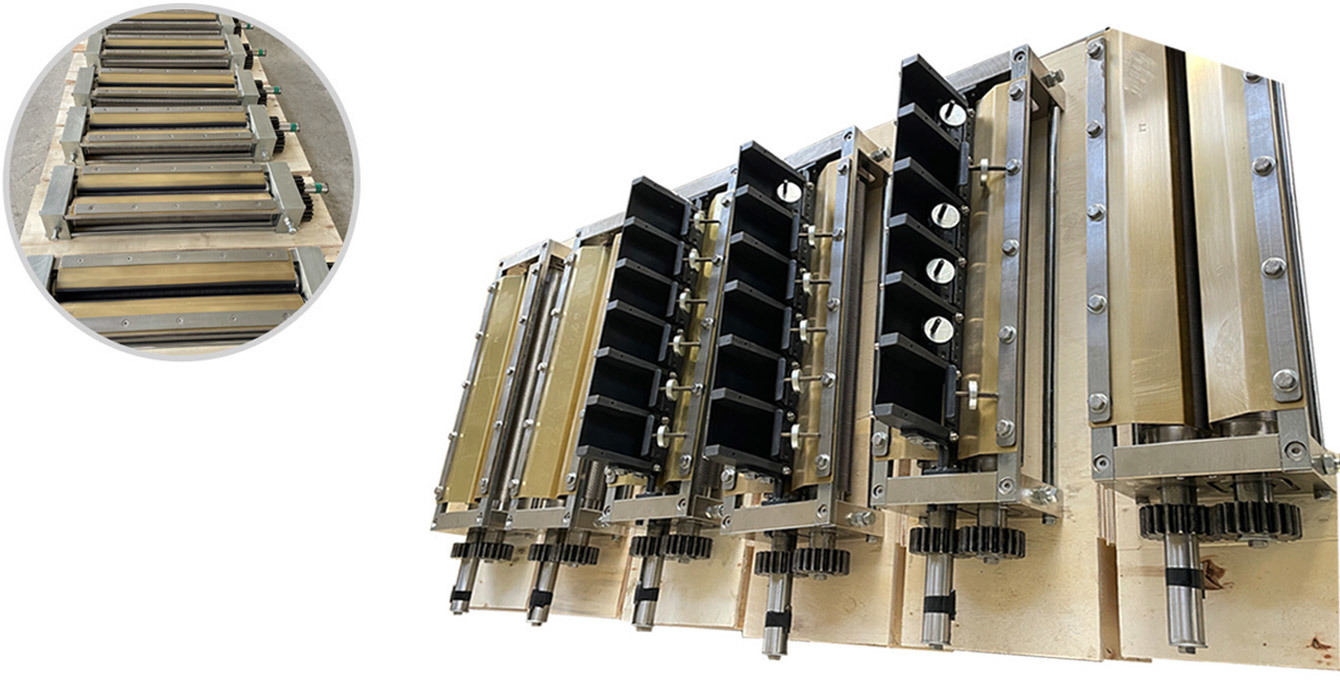

Rolling machine

Boiling noodle machine/ steam noodle machine

Noodle cooling machine

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!

Recommended Products