Chow mein noodle making machine

Keywords:

Chow mein noodle making machine

- Description

-

Chowmien noodle machine also called hand made noodle mcahine, as the name suggests, has manual assistance in production and is not a fully automated assembly line.

Due to the special shape of the chowmein noodles, there is currently no mature process to fully automate their production. It is necessary to manually shape the corresponding dough and place it in a plastic box. Usually, the shape of the chowmein noodles can be bird's nest or folded.

The chowmein noodle production lines use high-pressure steamers, which take about 2-3 minutes to steam the noodles. This makes the steamed noodles softer, more thoroughly sterilized, and extends their shelf life. After steaming, put the noodles into a noodle box, and then the noodle box enters a dryer for drying. Mesh belt is made of stainless steel 304 material, and the drying time is about 40 minutes. The output ranges from 250 kilograms to 1200 kilograms per hour.

Process: Flour mixing --- aging ---- dough pressing ---- rod hanging ---- high pressure steaming ---- put noodle into box by hand ---- drying ---- cooling ----- packing.

Product parameters

Model

Capacity

Power(kw)

Area(L*W*H)

Steam consumption

Worker

330

250kg/h

25

25x10x3

1000kg/h

9

350

400kg/h

40

35x10x3

1200kg/h

10

450

500kg/h

50

40x10x3

1400kg/h

12

550

630kg/h

65

45x10x3

1600kg/h

14

650

900kg/h

75

50x10x3

1800kg/h

16

800

1100kg/h

90

60x10x3

2000kg/h

18

PRODUCT DETAILS

Alkali water mixing and measuring system

Flour mixer

Dough aging machine

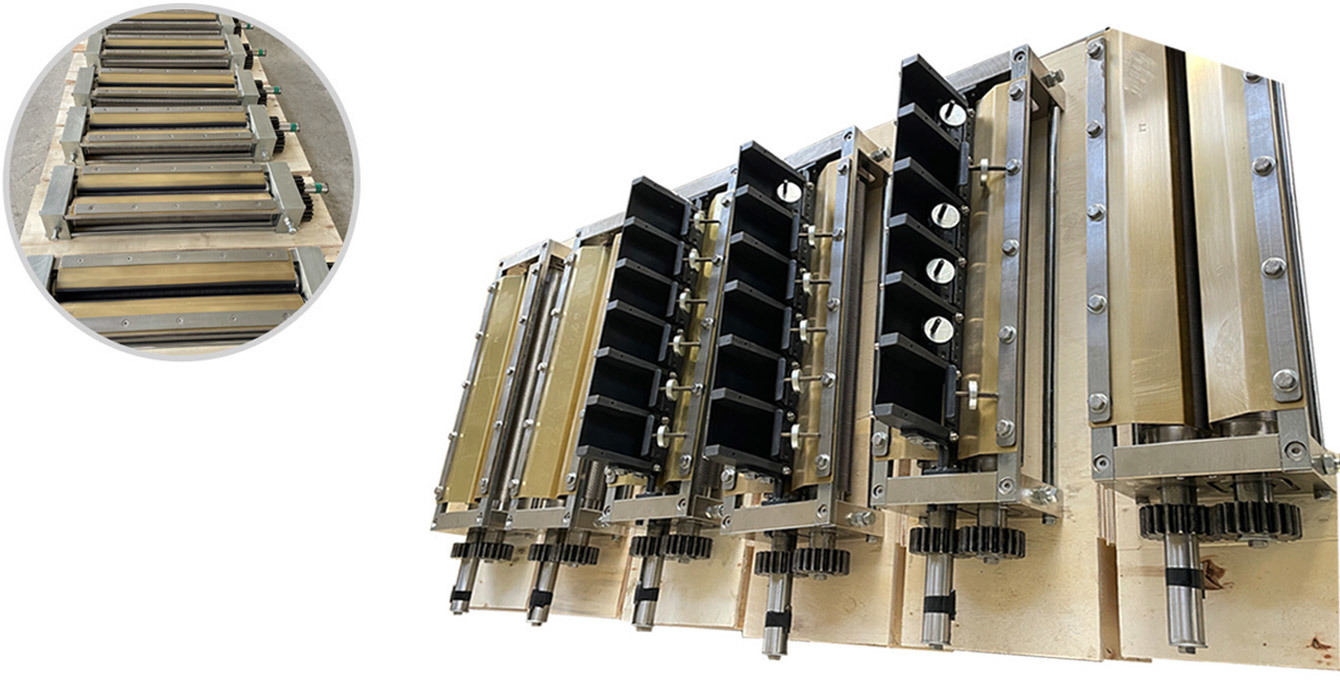

Rolling machine

High pressure steaming pot

Net belt drying machine

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!