Non-fried instant noodle making machine

Keywords:

non-fried instant noodle making machine

- Description

-

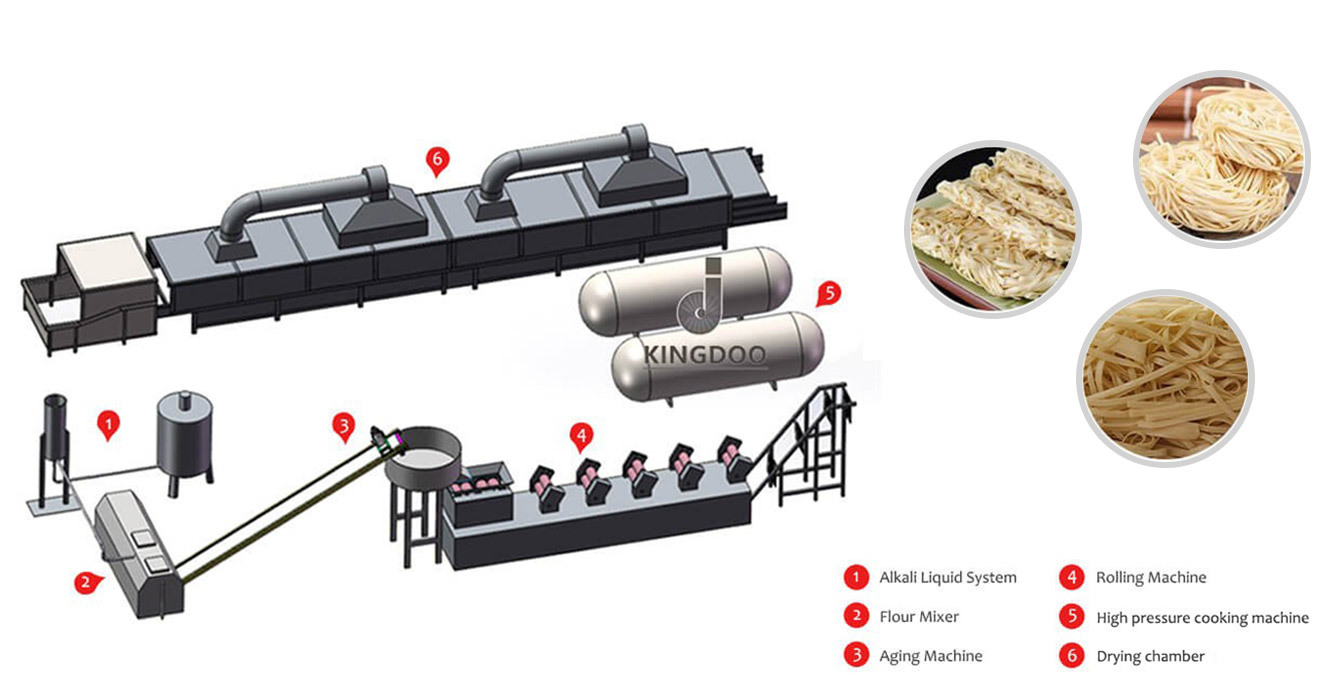

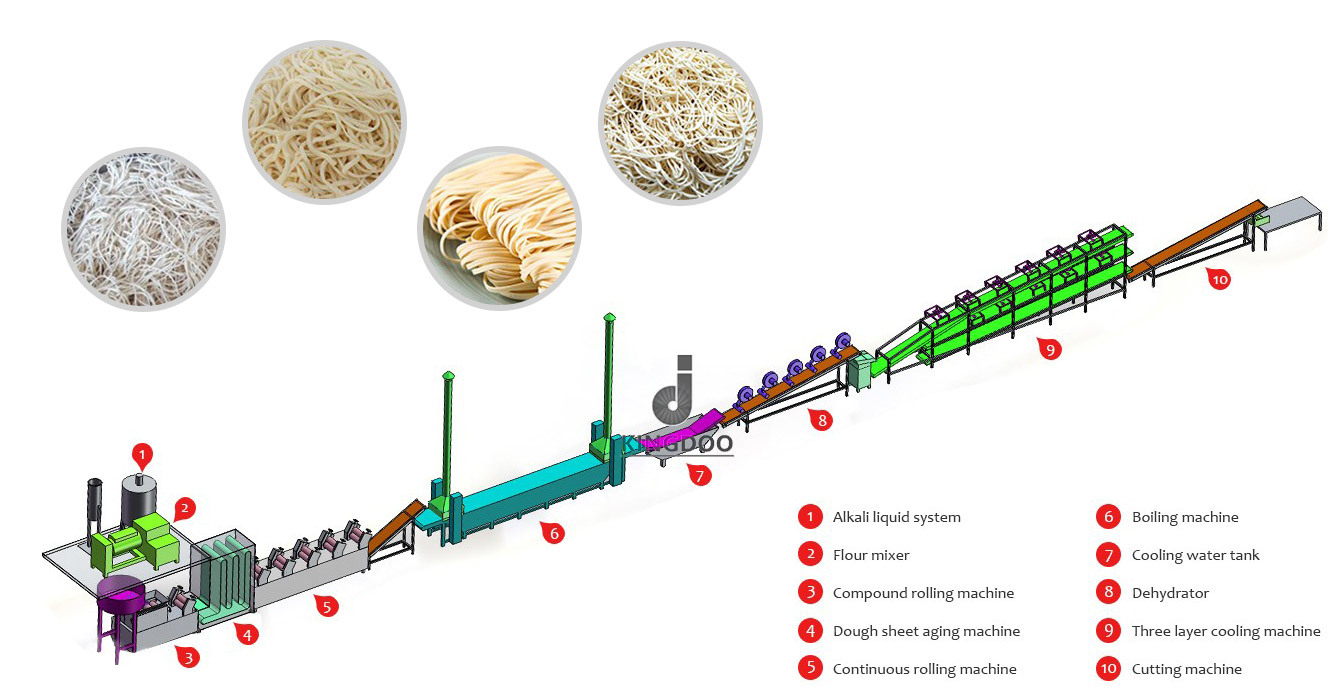

Non-fried instant noodles production line includes salt water mixing and measuring, flour mixing,dough aging, dough pressing, steaming, cutting and dividing, drying, air cooling, packaging. The entire line adopts steam heating method and it can produce square dried noodles or circular dried noodles, with a production capacity 20000 to 300000 pieces in 8 hours.

ADVANTAGE

1.Healthier Option:

●Non-fried instant noodles are often perceived as a healthier alternative to fried ones, as they typically contain less oil and fewer calories.

●Health-conscious consumers may prefer non-fried options due to reduced fat content.

2.Lower Oil Consumption:

●The production of non-fried instant noodles requires significantly less oil compared to the frying process used in traditional instant noodle production.

●Reduced oil usage can contribute to cost savings and may appeal to consumers seeking lower-fat options.

3.Extended Shelf Life:

●Non-fried instant noodles often have a longer shelf life compared to fried varieties, as they are less prone to issues such as rancidity.

●The extended shelf life can be advantageous for both manufacturers and retailers in terms of storage and distribution.

4.Versatility in Ingredients:

●Non-fried noodle recipes can incorporate a broader range of ingredients without concerns about their impact on frying processes.

●This versatility allows for the inclusion of various grains, fibers, and functional ingredients to meet diverse consumer preferences.

Product parameters

Model

power

Steam consumption

Dimension(m)

(multi- layer steamer)Worker

30,000pieces/8h

50kw

1000-1200KG/H

50*5*4

4

60,000pieces/8h

65kw

1500-1700KG/H

55*5*4

4

80,000pieces/8h

80kw

2000-2200KG/H

65*6*4

5

120,000pieces/8h

95kw

2400-2600KG/H

75*6*4

5

160,000pieces/8h

115kw

2800-3000KG/H

85*7*4.5

5

200,000pieces/8h

130kw

3200-3400KG/H

95*8*4.5

6

250,000pieces/8h

140kw

3600-3800KG/H

105*8*4.5

6

300,000pieces/8h

155kw

3800-4000KG/H

120*10*4.5

6

PRODUCT DETAILS

Alkali water mixing and measuring system

Flour mixer

Dough aging machine

Rolling machine

Steaming machine

Cutting and dividing machine

Hanging basket dryer

Cooling machine

Send Inquiry

NOTE: Please leave your email, our professional person will contact you asap!